SATNEWS

LIA Aerospace, a start-up specializing in the development and commercialization of space technology, held an event to review its latest achievements and outlined its next projects.

Recognized as the first company in the world to launch a reusable rocket powered by biofuels, LIA recently presented its own propulsion systems for satellites and spacecraft.

“Satellites are not always deployed into their target orbit with the rocket or launcher. Often, orbital maneuvers are required after launch to achieve the desired orbital parameters. Therefore, there is an evident need for reliable and cost-effective propulsion for the last-mile delivery in space. That’s where LIA Aerospace comes in,” explains Dan Etenberg, CEO of the company.

This year, LIA’s team designed the BP100 and BP200 propulsion systems, which can carry over 250 kg of payload, and utilize up to 230 kg of sustainable and storable propellants based on hydrogen peroxide and kerosene or alcohol-based fuels. They enable the circularization of the geosynchronous Earth orbit (GEO), and the transition from the geostationary transfer orbit (GTO). “In simple terms, we sell green and low-cost propulsion systems that allow satellites and spacecraft to autonomously travel through space,” clarifies Etenberg.

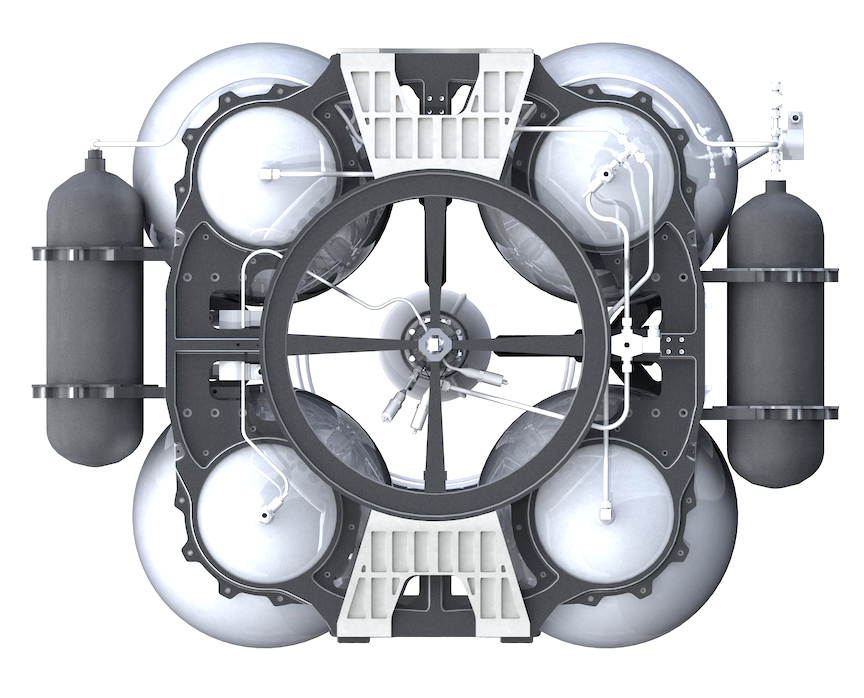

BP100

Bi-propellant, green, non-toxic, and non-cryogenic propulsion systems for orbital change and maneuvering, targeting small satellites and spacecraft.

Restartable, TVC for simplicity and cost-effectiveness.

This innovative development allowed LIA Aerospace to secure a place in the Incubation Program of the European Space Agency over the past year, open an office in the United Kingdom, and participate in various industry events across Europe, in cities such as London, Paris, and Helsinki, as well as in the United States.

BP200

Bi-propellant, green, non-toxic, and non-cryogenic propulsion systems for orbital change and maneuvering, targeting small satellites and spacecraft.

Restartable, TVC for simplicity and cost-effectiveness.

Back in Argentina, Dan Etenberg organized a private event for colleagues, suppliers, and investors on Tuesday, April 25. There, the LIA team performed a test on one of its engines with a heatsink configuration. The test confirmed that the flow, pressure, distribution, and stability parameters are correct to produce the sixth iteration of their KX11 engine. Etenberg also outlined LIA Aerospace’s phased growth, investment, and expansion plan from 2023 to 2025 to enable the sale of their products, and he announced an upcoming round of investment.

The event took place at the Aeronautical Technology Industrial Park (PITAM), in Morón Argentina, where LIA will install its new operational facilities by the end of the year. These new facilities will include offices, a test bench, manufacturing space, qualification facilities, and a clean integration room. Additionally, LIA signed an agreement with the National Technological University of Argentina as part of the Satellite and Aerospace Empowerment Program of the Secretariat of Knowledge Economy. This agreement enables collaborative research between UTN professors and students, to perform numerical computational simulation of the company’s engines, optimizing their performance and production timelines.

“LIA stands out for developing aerospace technology in record time and cost: while the average production time for propulsion systems of this kind is 24 months, we can produce them in 6 months and at 20% of the market price. Our new products are a clear testament to the extraordinary capabilities of the LIA Aerospace team,” concluded Etenberg.